Disclaimer: As I've mentioned before, don't take my posts here as the final word on anything. I feel the need to say this because I think my writing style sometimes leads people to assume that I know more than I really do. That would be an incorrect assumption. Honestly, even on my best days, I'm little more than a hack. Ignore my writing style and just know that my intention here at this time is not to provide answers, but to hopefully play a small part in figuring out what questions we should be asking.

ARCape wrote:

...That was till I decided to rip my mac apart & get to the cpu & gpu to do the all famous reapplication of the thermal compound to both. I dont know if I was lucky or the problem really is just a bad case of thermal compound...

My guess is that you were lucky. Specifically, I suspect that the order in which you tightened down the heatsink screws (possibly combined with thicker compound?) slightly altered the mount pressure in favor of a broken solder joint. To paraphrase Spock from episode # 35 TOS, random chance seems to have operated in your favor.

I've seen this pop up a couple of times, but it never seems to be permanent. This person, posting in another thread in August, said that it lasted about a month:

I managed to change the thermal paste about three months ago. It worked at first, but one month later, GPU problems appeared again hence I had to install smcFanControl and put my fans up to 6200 RPM.

Generally, I am highly in favor of replacing factory compound. I did mine when it was only a few days old and got about an 8 degree difference at load. This is about what most people report on the 2011 models. Very nice for about 40 minutes of work. Cooler temps mean better performance (less throttling and more thermal headroom for turboboost to do its thing).

That said, let me get a couple of things out of the way in relation to this discussion:

1) Thermal compound will not repair a broken solder joint.

2) If I am correct above about why this seems to work for a short while for a few people, then there also exists a possibility that you could make things worse. That is, if you've managed to lock down to the HD3000 and have bought yourself some time to see if Apple is going to do anything, I'd be very cautious. I could also, of course, be completely wrong about all of this.

Why do I even bring it up then? For those planning to do it anyway, I want to provide some additional information that is missing from the popular links and videos. I also want to revisit a previous statement that I made on the subject and I'm curious about those who have had the motherboard replaced only to experience the same problem again after a short time. There may be some questions worth asking for those who have had the motherboards replaced and have not yet experienced any problems.

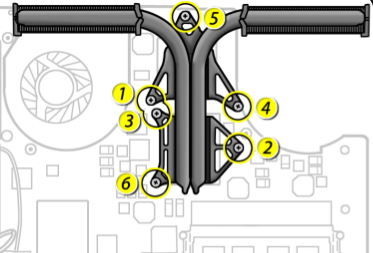

Reattaching the heatsink:

The screws should be tightened down in this order:

The specific wording from Apple's Technician Guide is this (page 213):

"Install heatsink screws in the order shown, 1/2 way first, then tighten the rest of the way."

The wording isn't perfect, but they mean for you to follow the same pattern for both the "1/2 way" and "rest of the way" steps.

This would have come from Apple engineers and I've seen no indication that it isn't the exact best way to do it to get the most even distribution.

My advice on choosing a compound: In this case, I would suggest paying very little attention to the benchmarks and endless pages of debate about which product might be a third of a degree cooler than the other. Depending on how information is presented, the graphs can look impressive. But when you realize that these graphs only indicate about a three degree difference between the top 20 or so products and the results should be read with a 2 degree margin of error, there isn't that much difference. By all means, get a top tier product, but focus more on the differences. Focus more on things like viscosity, texture, and its ability to perform well under different amounts of pressure. Generally a low viscosity compound is more desirable when two well-finished surfaces meet perfectly and high viscosity compounds are more desirable when dealing with imperfections. The word "tacky" is sometimes used as a negative description in these reviews. It's true that a "tacky" compound can be a little more difficult to work with, but it can also be very helpful in some situations.

Mine fit together very well and I got good results from my favorite low viscosity compound on both chips, but I don't think that's true of all of these. I think we're dealing with some significant manufacturing variations in these heatsinks.

Which brings me back to a previous comment that I made on this subject. About 10 pages back, I said that I think the excessive use of thermal compound at most only plays a role in causing these problems to appear a little sooner than later. All else being equal, that's a true statement. Tests show only a few degree difference between the right amount and way too much. The rest of the difference that we see when reading user "before & after" reports comes from the higher quality of the compound chosen. But taking a step back from everything that I think I know about this, things are not always going to be equal when you're dealing with two heatsinks on the same assembly.

For an example, we can take another look at the popular iFixit teardown:

To my eye, the CPU part (top) looks okay. Yes, a lot was used, but the extra got squished out the sides. And it looks like there was a good flat meeting between the heatsink and the CPU die. On mine, both chips looked like that. That bottom picture, though? I'm not even sure what we're looking at there. If this were my machine, I'd consider using two different types of compounds for reassembly. At minimum, I think we're looking at different mount pressures here, but it's not obvious to me that the GPU die and heatsink have ever even met or would recognize each other in a bar. It's not the amount, but the quality of factory compound that could be problematic in this case. If the bulk generic stuff is being left to play the role of thermal conduit on its own in some cases, that would lead me to believe that this could be playing a bigger role as contributing factor. It would necessarily mean that more heat is being displaced through the PCB.

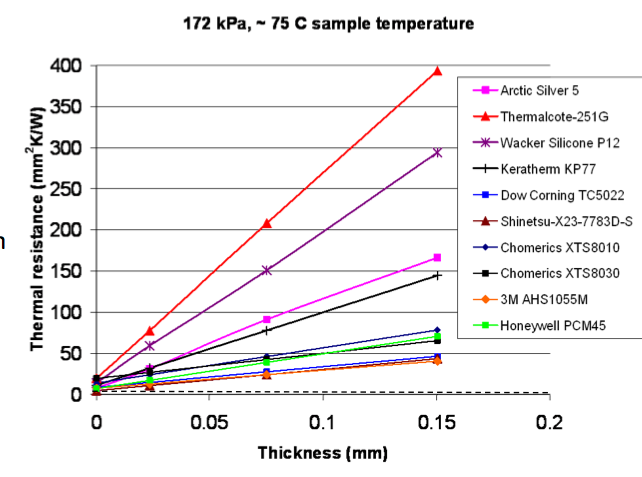

To understand what I mean, see this 2009 study by The United States Department of Energy. Yes, it's a little dated, but it mentions compounds that are still popular today. Also, it's far more sophisticated than the average benchmark comparison on an overclocking website. In this image, you can see how 1/20th of one millimeter can effect the thermal resistance of some popular compounds:

Thermal compound isn't really intended to play the role of thermal conduit on its own. It's intended to fill the micro-imperfections between the surfaces that meet. Still, as you can see from the graph, some do far better than others when asked to play this role. And all of these are likely far superior to the generic OEM stuff.

In another example, in this thread, the owner got "not so satisfactory" results from AS-5 and "really great" results from MX-4. There would be no reason in the world for this if we were talking about things that fit together well. Those are both fine quality products. But MX-4, even though it doesn't stand out in any one particular category, can perform well under a wide range of conditions. With AS-5, you're instructed to spread it out flat on this type of bare die surface. A lot of user reports that previously confused me make sense when looked at in this context.

In this picture, we appear to be looking at an uneven spread:

Much thicker at the top. Why? Were the screws not tightened in the right order? I don't know much about automated assembly, but I assume that this is still something that's done by hand? Or is the problem here with the heatsink itself? Or the heatsink mount points? Also notice that we're already seeing signs of cracking in the compound at just under the two year mark for this photograph.

If you're using a new board with the old heatsink, it might be worth investigating? I don't know if the depot repair uses the same compound that is used at the factory, but I'd imagine it's still a bulk generic low-quality type of stuff. If there is an actual gap between the two surfaces, corrective measures beyond a different type of compound may be in order. Ask a trusted technician about a new heatsink, a shim, or other modification. A repair person who works on all major laptop brands will already be well familiar with this type of issue.

For those planning to redo the compound yourself, I'd take a minute to study the old stuff before cleaning it up. I might then do a couple of test applications before putting it all back together. Put a few small drops of compound in several locations and then screw down the heatsink following above instructions. Then take it back off and see if you're satisfied with what you find. Are they even? To give yourself a baseline for comparison, put about the same size drop of your chosen compound between two flat surfaces (a mirror and a small piece of glass would be very nice for this). Slowly press down on the glass and you can see for yourself how the compound spreads.